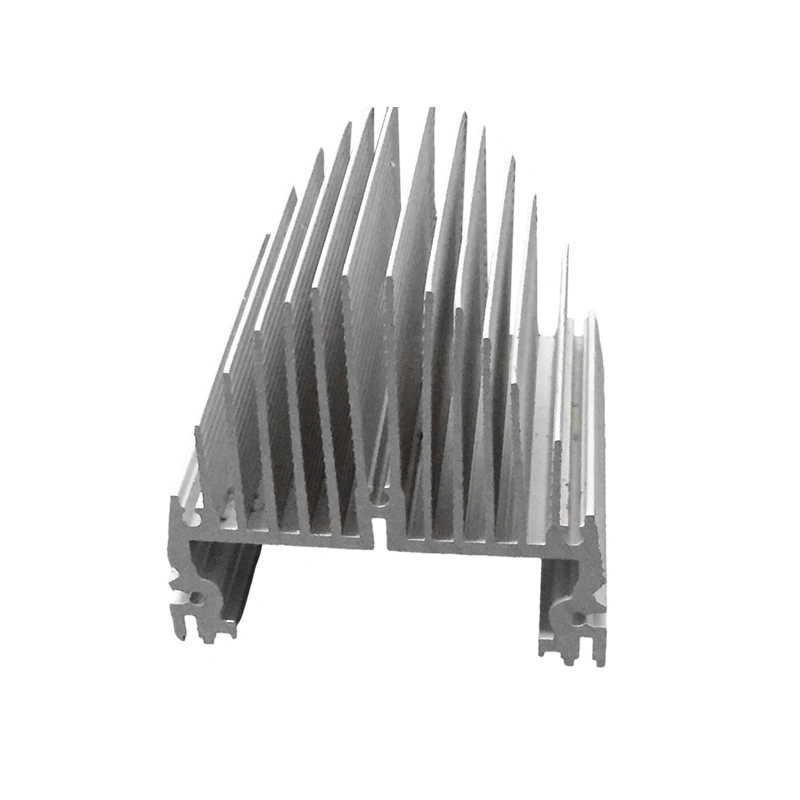

Manufacturer OEM/ODM CNC Turning Milling Machine Parts Service High Precision Machining for Auto Motorcycle Parts

Basic Info.

| Model NO. | P-001 |

| Tolerance | +/-0.001mm |

| Sample Cost | According to Your Drawings |

| Delivery Date | 4-15workingdays |

| Color | as Customer′s Requirement |

| Materials | Metal |

| Machine Type | 5/4/3 Axis |

| Process | Cutting, Turning, Milling, Machining |

| Model No. | Stainless Steel/Aluminum Machined Parts |

| Transport Package | Cartons |

| Specification | Customized |

| Trademark | Kumore |

| Origin | China |

| HS Code | 3715 |

| Production Capacity | 500000/Month |

Product Description

Product Parameters| Process | Cutting, Turning, Milling, Machining |

| Tolerance | +/-0.001mm |

| Roughness | Ra≤0.1mm |

| Specification | OEM |

| Material | Aluminum: AL6061,AL6063,AL6082,AL7075,AL5052 |

| Stainless steel: 201,301,304,316 | |

| Other materials as customer's reuqiement | |

| Surface Treatment | Anodized, Plating |

| Electropolishing, Mirror polishing, Brushing | |

| Silkscreen printing, Pad printing | |

| Packaging | 1.Standard carbon box |

| 2.Packaging as customer's requirement | |

| Inspection | 1.Final inspection before delivery. |

| 2.Third Party inspection available as per requirement. | |

| Certification | ISO9001:2015 |

| Application | Automobile, Aerospace/aircraft, Consumer Electronics |

| Medical Device, Smart Home, Industrial Robot,Industrial Equipment, Auto Parts,Furniture, Sports equipment |

Guangdong kumore technology co.,Ltd is one of leading manufacturers of auto parts with CNC maching production line in China.Our CNC machining service including processing, mechanical equipment and accessories. Mainly for CNC hardware processing and mechanical parts processing, precision metal stamping, auto parts, motorcycle parts. After 8 years of development, we have established our own mature supply chain from CNC machining center, injection molding machine, die-casting workshop, stamping workshop and rubber mold workshop.We also own our rich experience of oversea sale team to offer you one-stop products solution.And our R&D team is also your strong power to make your idea to come true reality.As long as you have passion and ideas to create your own products, we will provide unlimited support to help you realize their value.Welcome to send us inquiry !

CertificationsPackaging & Shipping

FAQ

Q1:Are you a manufacturer ?

A1:Yes,we are manufacturer.

Q2: How can I get the production quotation?

A2: Send us an inquiry or e-mail with drawings and materials, we will reply you as soon as possible.

Q3: What's kinds of information you need for a quote?

A3: Please kindly provide the product drawing in PDF/3D /2D/STEP / IGS/DWG

Q4:How can I get the quotation If we don't drawings ?

A4:We are glad to receive your samples, pictures or detailed size of the draft in order to accurately quote.

Q5. Can we get some samples before mass production?

A5: Sure,we accept to send you sample to test the quality before the order.

Q6:How about the delivery date?

A6:Generally, 1-2 weeks for samples, 3-4 weeks for mass production.

Q7:How to sart it If we are not familiar with material,surface treatment or something?

A7:We can give you sloution as your product requirement.

Q8:How about the after sales services

A8:We will seend you sample to test the quality before order ,the goods are not meet the requirement, we will provide you with solutions to meet your requirement.